考虑您自己的小型制造工厂,该工厂不需要任何许可证即可设置。当然,您已经看到许多不需要许可证的家庭制造行业。您无需许可证即可购买和使用榨汁机。如果您想将 3D 打印机用于商业用途,我们得到的消息是,很少有制造单位申请批量销售许可证。但是,对于商业生产(for commercial production)和打印机的输出,(for the output of the printer)情况就是如此。您不需要许可证即可拥有 3D 打印机并打印供个人使用的东西。

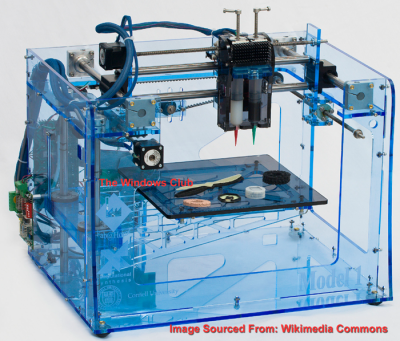

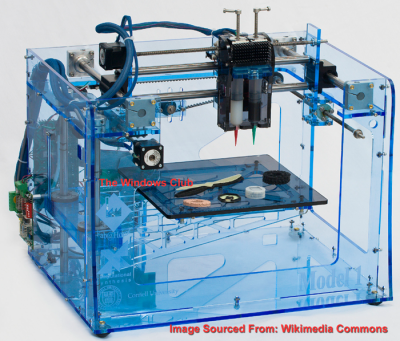

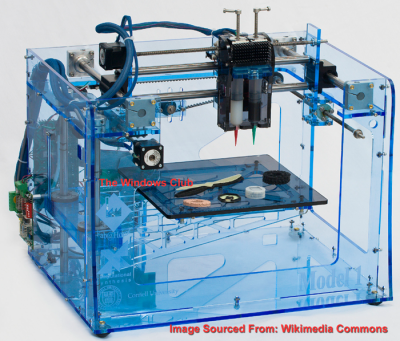

什么是 3D 打印机

3D 打印是将您的数字设计转换为实体 3D 对象的过程。这个想法对某些人来说可能看起来很新颖,但它实际上是在 19 世纪后期发展起来的,并已广泛用于多个行业的原型设计。虽然改变的是,这项技术终于向消费市场开放,不再局限于制造业。

3D 打印机如何工作

需要遵循一组简单的步骤来打印 3D 原型。

第一步是使用任何计算机辅助设计 ( CAD ) 软件对您的想法进行数字建模。创建蓝图后,应用程序将其分解为多个水平数字横截面,打印机可以理解并以精确定义的规格再现。然后将完成的设计发送到 3D 打印机。

有趣的是,3D 打印实际上采用了“增材”制造工艺,这意味着实体物体是通过添加原材料层来创建的,而不是传统制造中使用的“减材”工艺,通过这种工艺,可以通过选择性地去除材料来构建物体。原料以获得预定义的结构。

在此之后,选择打印机将用于打印对象的材料,这可以从包括塑料、橡胶或金属在内的众多选项中进行选择。打印过程包括通过连续层创建对象层。不同的打印机采用不同的技术来创建这些层。打印机继续在层的顶部沉积一层,直到完成。各个层自动合并以创建 3D 原型。

打印过程通常需要几个小时到一整天的时间,具体取决于要打印的对象的复杂性和大小。

3D打印机能做什么

理论上,任何可以数字化可视化的东西都可以打印出来。目前唯一的限制是对可用于 3D 打印的尺寸和材料的限制。它被广泛用于艺术、工业、空间研究、医疗保健和其他几个不同的行业。

以下是 3D 打印机可以制作的一些示例:

1. 在医疗保健领域,3D 打印已被用于制造助听器、假肢和牙科固定装置。研究人员正致力于打印可以移植到人体中的人体组织。

2. NASA已经使用 3D 打印来制造火箭和宇宙飞船的部件。科学家们已经在研究可以在零重力下在国际空间站(International Space)上使用的 3D 打印机。

3. 像波音(Boeing)这样的公司实际上是在使用 3D 打印来制造零件来制造一架真正的飞机。汽车公司广泛使用 3D 打印来构建发动机和车辆其他部件的原型。

4. 爱好者和艺术家正在使用 3D 打印来创造性地表达自己,并创造以前被认为不可能实现的形状和结构。各种形状和颜色的玩具(Toys)、雕塑、礼品和珠宝都是使用 3D 打印制作的。

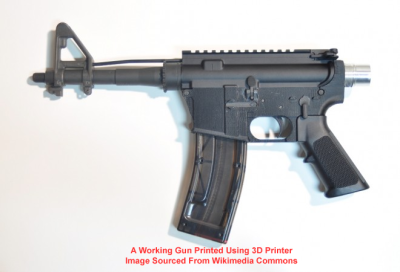

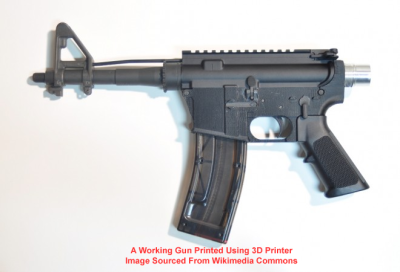

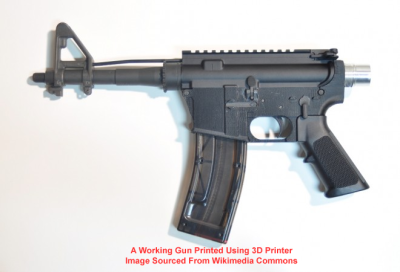

5. 令人不安的是,3D 打印已被用于制造能够发射实际子弹的枪支原型。它也可用于锻造珠宝和艺术品。

(3D) 打印的未来

3D 打印是一项颠覆性技术,有可能改变多个行业的多个方面。3D 打印的可能性是无限的。3D 打印在工程、医疗保健、建筑、建筑、消费电子和空间研究方面的创新令人难以置信。

确实,3D 打印可以不利地用于批量制造武器,甚至可以用于锻造高价值的艺术品和珠宝。遏制非法使用的一种方法是强制购买 3D 打印机的制造许可证。但是,也有一些针对反盗版的规定。

底线:(BOTTOMLINE:) 3D 打印的建设性应用(优势)远远超过负面使用可能性(3D 打印机的劣势和危险)。我让你来决定如何利用这个行业来做更多的好事而不是坏事。

请在下面的评论框中告诉我们您对 3D 打印机的看法。(Please let us know your point of view on the 3D printers in the comment boxes below.)

协助:(ASSISTED BY:)斯瓦加特·卡纳尼。

What Is 3D Printer? Should A License For 3D Printing Be Mandatory?

Consider your own mini manυfacturing plant that does not require any license tо sеt up. Of course, you have seеn many home-basеd manufacturing indυstriеs that don’t require a license. You won’t need a license to buy and υse a juicer. If you want to go for commercial usage of a 3D printer, we got the news that few manufacturing units aрplied fоr a license for bulk sales. However, that is the case for commercial production and for the output of the printer. You don’t need a license to own a 3D printer and to print things for personal usage.

What Is A 3D Printer

3D printing is the process of converting your digital designs into solid three-dimensional objects. This idea might seem novel to some but it was actually developed in the late nineteenth century and has been widely used for prototyping in several industries. Although what has changed is that this technology has finally opened up to the consumer market and is no longer restricted to manufacturing industries.

How Does A 3D Printer Work

A set of simple steps needs to be followed to print a three-dimensional prototype.

The first step is to digitally model your idea using any computer-aided design (CAD) software. Once a blueprint has been created the application breaks it down into multiple horizontal digital cross-sections in a manner which the printer can understand and reproduce in the exact defined specifications. The completed design is then sent to the 3D printer.

Interestingly enough 3D printing actually employs the “additive” manufacturing process, this means that the solid object is created by adding layers of the raw material as opposed to “subtractive” process used in conventional manufacturing, through which an object is built by selectively removing the raw material to obtain a pre-defined structure.

After this a material is selected which the printer would use to print the object, this can be chosen from a plethora of options including plastic, rubber or metal. The printing process consists of creating the object layer by the successive layer. Different printers employ different techniques for creating these layers. The printer continues to deposit a layer on top of the layer until the completion. The various layers are automatically amalgamated to create the three-dimensional prototype.

The printing process can typically take anywhere between a few hours to entire days depending on the complexity and size of the object to be printed.

What Can A 3D Printer Make

Theoretically, anything which can be digitally visualized can be printed. The only limitation at present is the restriction on size and material which can be employed for 3D printing. It is being extensively used for art, industries, space research, health care and across several other varied industries.

Here are some examples of what a 3D printer can make:

1. In the health care domain, 3D printing has been employed to create hearing aids, prosthetics limbs, and dental fixtures. Researchers are working on printing human tissues which could be transplanted in human bodies.

2. NASA has employed 3D printing to build parts of rockets and spaceships. Scientists are already working on 3D printers which can be employed in zero gravity to use it on the International Space station.

3. Companies like Boeing are actually using 3D printing to build parts to build an actual airplane. Automotive companies are extensively using 3D printing to build prototypes for engines and other parts of the vehicles.

4. Hobbyists and artists are using 3D printing to creatively express themselves and to create shapes and structures which were previously considered impossible to implement. Toys, sculptures, gifts, and jewelry have been created using 3D printing in all shapes and colors.

5. Disturbingly enough 3D printing has been employed to create prototypes of guns that are capable of firing actual bullets. It can also be used for forging jewelry and art.

The Future Of (3D) Printing

3D printing is a disruptive technology having the potential to transform multiple aspects of several industries. The possibilities of 3D printing are limitless. The innovation 3D printing can spur in engineering, healthcare, architecture, construction, consumer electronics, and space research are mind-boggling.

It is true that 3D printing can be adversely employed to create weapons in bulk or can even be used to forge high-value art and jewelry. One way to contain illegal usage is to make a manufacturing license mandatory for those buying 3D printers. But then, there are several regulations in place for anti-piracy too.

BOTTOMLINE: The constructive applications (advantages) of 3D printing far outweigh the negative usage possibilities (disadvantages and dangers of 3D printers). I leave it up to you to decide how the industry can be used for more good than bad.

Please let us know your point of view on the 3D printers in the comment boxes below.

ASSISTED BY: Swagat Karnany.